| A limestone and coke stock silo is positioned at the top of the kiln. The limestone is fed intermittently, passes through an enclosed rotary damper and rotary chute, and is supplied to the kiln. Thermal energy loss from the kiln walls is minimal. In the case of hard burning, a clinker block breaker is used and the limestone is discharged after passing through a three-stage closed damper. Exhaust gas is cleaned by means of bag filters before release into the air. |

- Thermal efficiency of 80% or higher

- Capable of hard or soft burning

- CO2 concentration of 40% or higher

|

|

|

|

|

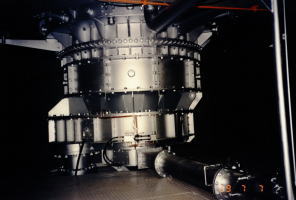

| Rotary Breaker |

|

Lime Discharge Unit |

|

|

|

|

|

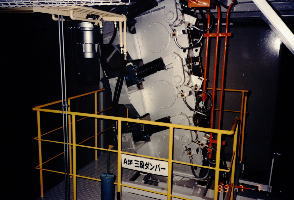

| Three-stage Damper |

|

|

|

|

|